What is Innovation in EPC Project Execution?

In general, "innovation" is probably one of the most sought improvements in modern business, but is also one of the most undertood. Everybody wants to be innovative, but it is rare in actual fact in most businesses. This is especially true in the engineering-construction industry.

How Innovative Are We in EPC Execution Today?

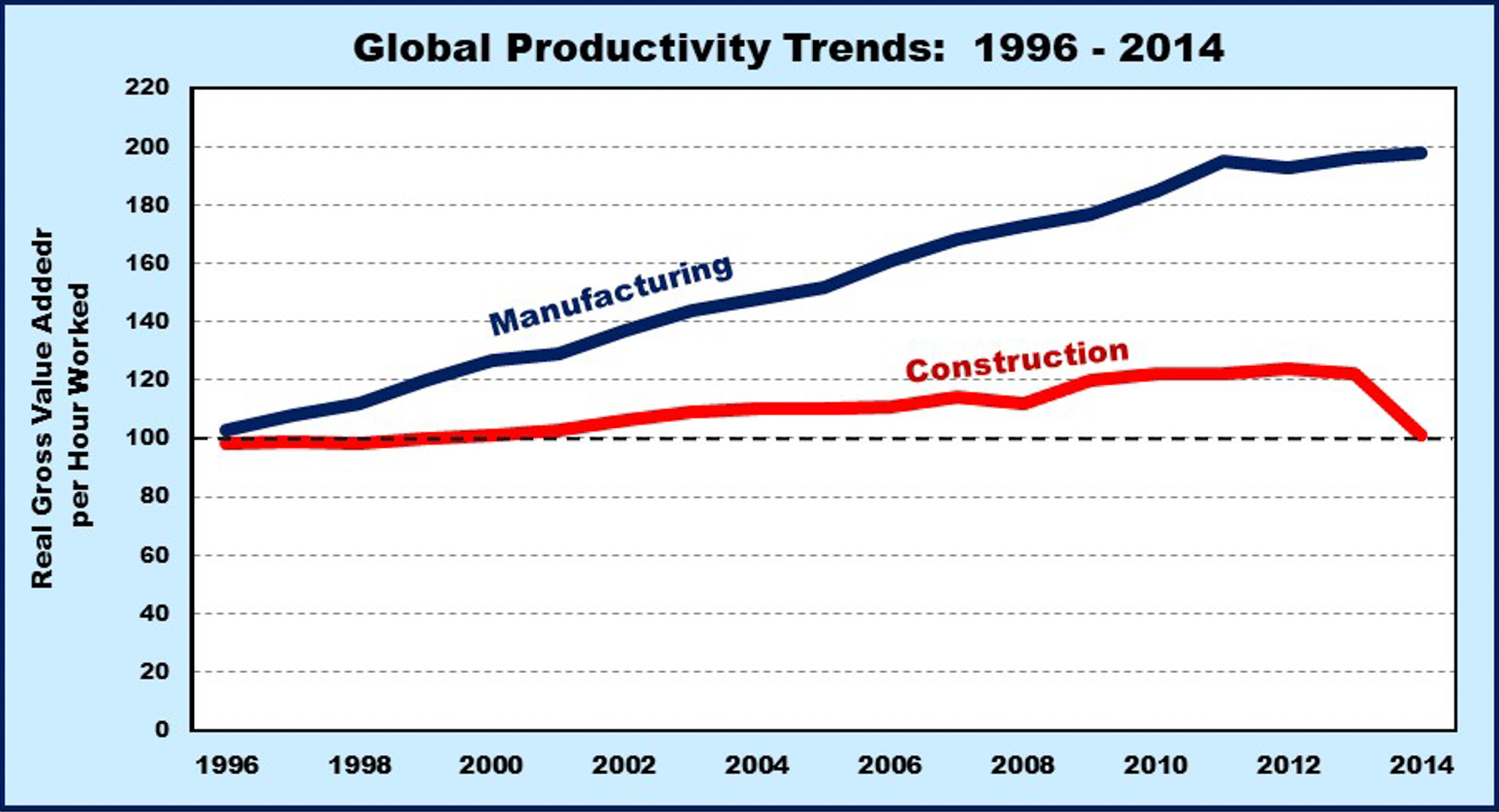

Sadly, innovation in executing EPC projects is virtually non-existent, and there is striking evidence of this. Consider the difference in productivity improvement in manufacturing vs. construction over the past 25 years, as shown in the graph below.

Note that manufacturing productivity has nearly doubled during this timeframe while construction productivity has hardly improved at all. This is in spite of a tremendous amount of effort to improve the one area of EPC project execution that has the most impact on total project costs.

These efforts, which has yet have not had much overall impact, include some of the most popular and "hottest" new methodologies being introduced into today's engineering-construction industry: Advanced Work Packaging, digitization.

So what's wrong? There is no other conclusion than there is something fundamentally wrong with how we currently plan and execute projects -- something essential to true innovation that is missing in all the current "advances" being implemented. Perhaps it's because we have no clue in this industry about how to be innovative.

What Are Examples of Innovation in EPC Project Execution?

From a perspective gained from nearly 100 years of experience in this industry, we have been only two fundamental innovative shifts in planning and executing major EPC projects -- shifts that had a step-change change in approach as well as project and business outcomes.

1) In the 1970s, there was a switch in how projects were resourced. The execution of EPC activities performed within discipline groups was replaced with a project task force approach in which resources were assigned from discipline groups to a specific project

where the activities were performed.

2) In the 1980s, Pass Gates were inserted between the distinct development phases of an EPC project to ensure that the output of each phase provided a sound basis for work in the next phase prior to proceeding. These "gates" were necessary because of the immense pressure to "get on with the job."

These two innovations, which were nearly universally incorporated in the strategies for executing EPC projects, had a dramatic impact on improving project and business outcomes. EVERYTHING ELSE SINCE THEN HAS NOT!

This includes the introduction of massive amounts of computer hardware and software used in executing project activities in all phases of an EPC project. Clearly this is NOT the answer.